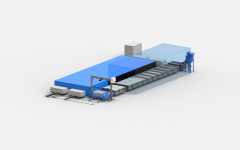

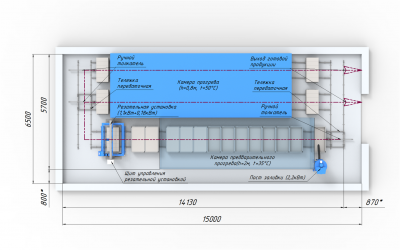

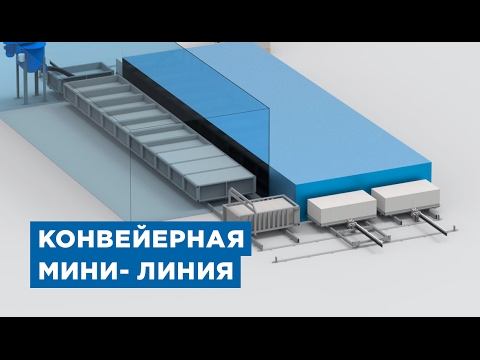

Aerocrete production mini-conveyor line, equipped by cutting machine, with capacity from 26 m3

Configeration

| Mechanical cutting unit of the mini-line | 1 |

| Mold sides (1,2×0,6×0,3 m for 12 gas-concrete blocks) (set) | 15 |

| Support for mechanical pusher | 3 |

| Penetrometer | 1 |

| Transfer cart | 2 |

| Mold bases (1,2×0,6×0,3 m for 6 gas-concrete blocks) with the metal bottom | 45 |

| Transfer rail track | 9 |

| Rail track for moveble molds | 42 |

| Sieve for pouring mixture into the mold | 1 |

| Scraper blade for cutting the top crust | 1 |

| Suspension mixer | 1 |

| Mixer-activator (0,25 m³) | 1 |

| Mechanical pusher | 2 |

Characteristics

| The required number of staff | от 4 People |

| Necessary water temperature | 50-60 C⁰ |

| Power consumption | 3 kWh |

| Necessary room temperature | от 15 C⁰ |

| Required space | 6,7х19х2 m |

Mechanical cutting unit of the mini-line

The mechanical cutting unit ASM-RM2 is a string cutting unit for gas-concrete blocks. This unit is used to get separate gas-concrete blocks of the necessary size from the manufactures mass of gas concrete. They are cut at the time of incomplete hardening – in 60-120 minutes after pouring. The block size can be adapted fast by changing the distance between the strings.

The silos for cement of “AltaiStroyMash” company provide for favorable storage conditions and protect the feedstock from moisture and other adverse external impacts. High quality steel 4 mm thick is used for designing our silos.

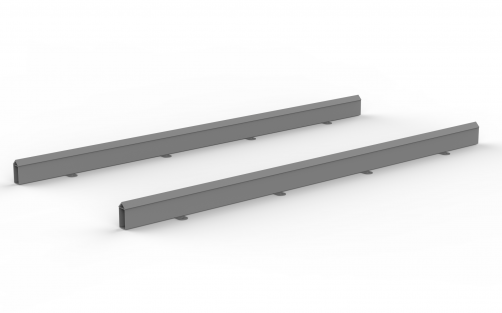

Mold sides (1,2×0,6×0,3 m for 12 gas-concrete blocks) (set)

The sides of the slip mold at the conveyor are made with high-precision laser slitting and provide for specific impermeability when assembled. With this set of sides, the mold can get ready for filling in 2-3 minutes after the finished products are removed from the mold base. The set provides for filling 12 blocks of standard dimensions 20х30х60 cm.

Support for mechanical pusher

The holdback is a metal construction for fixing the mechanical pusher which moves the molds to the heating chambers via rail tracks.

Penetrometer

The penetrometer (plastomer) defines the plastic strength of the gas-concrete mass and if it is ready for slitting. Its basic principle lies in the property of the concrete mixture to withstand the cone penetration.

Transfer cart

The transfer cart of the conveyor removes the mold bases between the two parallel railways.

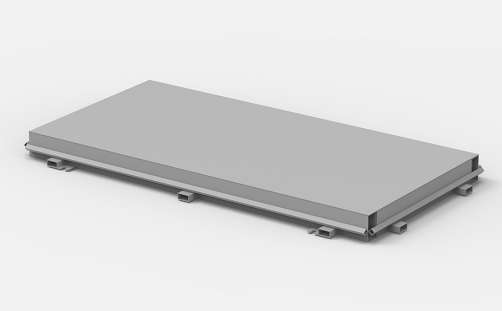

Mold bases (1,2×0,6×0,3 m for 6 gas-concrete blocks) with the metal bottom

Mobile mold bases of the conveyor provide for a highly practical mode of production since the major hubs are located stationary: the mixing unit, the slitting unit or the warming chamber.

Transfer rail track

The system of mold transfer within the conveyor consists mostly of major rail tracks and rail tracks for transfer carts. As a rule, they start assembling the line with this part.

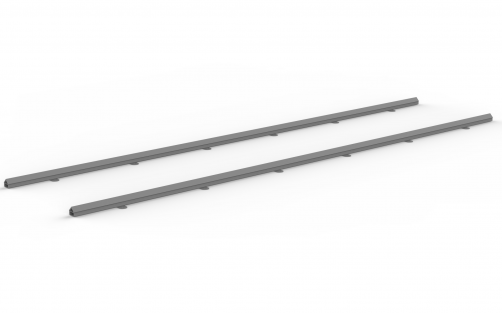

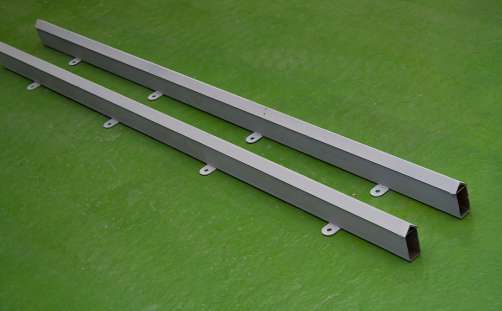

Rail track for moveble molds

This is the system for transporting the molds in the conveyor line from the mixer to the heating chambers and back. The assembling of the line starts from this part of the technological line on gas concrete production.

Sieve for pouring mixture into the mold

The sieve is applied to prevent the grease on the sides from being washed off at pouring the gas concrete mixture into the mold. It also prevents coarse fractions contained in sand from getting into the mold

Scraper blade for cutting the top crust

The scraper blade makes the top of the blocks more even and better-looking for the customer. It cuts the top crust neatly and the workroom will be clean.

Suspension mixer

The suspension mixer is necessary to prepare the gasifier which is usually aluminum powder. It is attached to the support rack of the block of dosing units or the skip hoist.

Mixer-activator (0,25 m³)

The mixer is intended to prepare the gas-concrete mixture, with a consistency of 400 - 800 kg/m3 out of cement, sand and water followed by pouring it into molds (to produce blocks).

The mixer can be operated stationary in a workshop under moderate temperature conditions due to GOST 15150-69 and cannot be operated at construction sites.

Description

A mini-conveyor type aerocrete production plant with capacity for 26 m³ per day. The plant consist of a stationary mixer, movable molds on the rails with manual mechanical pushers, and a semi-automatic cutting machine.