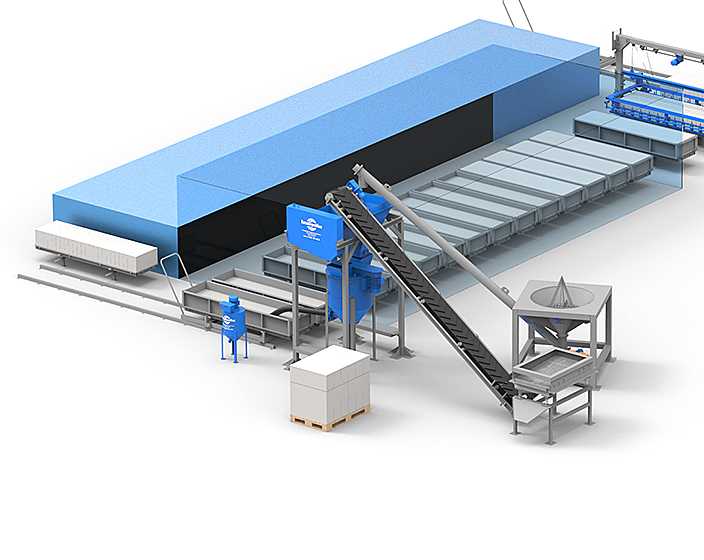

Оборудование для производства газобетона

EQUIPMENT FOR PRODUCTION OF GAS-CONCRETE BLOCKS

Since 2000 “Altaistroymash” company has been manufacturing professional equipment for production of gas-concrete blocks. The equipment possesses the state-recognized certificate. Eighteen years of experience, the lean manufacturing technologies of “Toyota” company, applying German laser cutting “Trumpf” for precise processing of each detail – these things guarantee the quality of the equipment for the production of non-autoclave gas concrete.

Our sets allow manufacturing gas-concrete blocks of high quality and flawless geometry. They all are of the same standard with non-autoclave concrete complying with the All-Union State Standard (GOST) of 1989.

We deliver production lines worldwide and provide for a two-year warranty period for all the components, as we control the equipment quality at each stage of production and sales.

Purchasing the line you get free technical assistance which includes the following:

Purchasing second-hand equipment, for instance at Avito website, you deprive yourself of warranty service and technical support of our specialists.

PRICES FOR GAS CONCRETE AND EQUIPMENT FOR ITS PRODUCTION

Non-autoclave gas concrete is applied for construction of cottages, houses, schools, hospitals, high-rise buildings, and malls. In the last 8 years, the demand for gas-concrete blocks has increased by 14 times and gas concrete accounts for 43%of the market share compared to other construction materials. The market price for gas-concrete blocks, regardless of the region, exceeds their net cost at least by 30%.

The material is popular depending on the geographical region. For instance, in Kazakhstan, the price for gas-concrete blocks is higher than in the countries where gas concrete has just started getting popular. Though even there the number of customers has increased by 27% compared with 2017. It depends on the active development of construction and state support of small and mid-size businesses.

PRICES FOR the EQUIPMENT FOR GAS CONCRETE blocks PRODUCTION

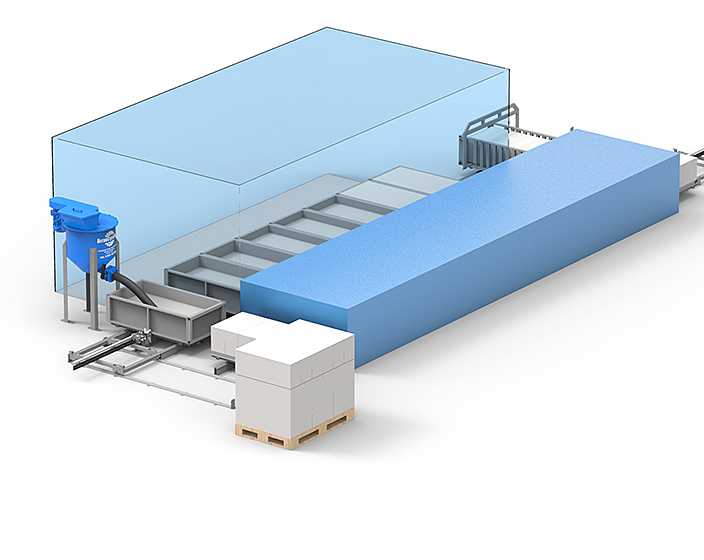

All the production lines are highly efficient due to minimal raw material consumption and little technological waste.

The basic equipment in the conveyor line with a productivity of 40 m3daily is cheaper than a foreign mid-class car.

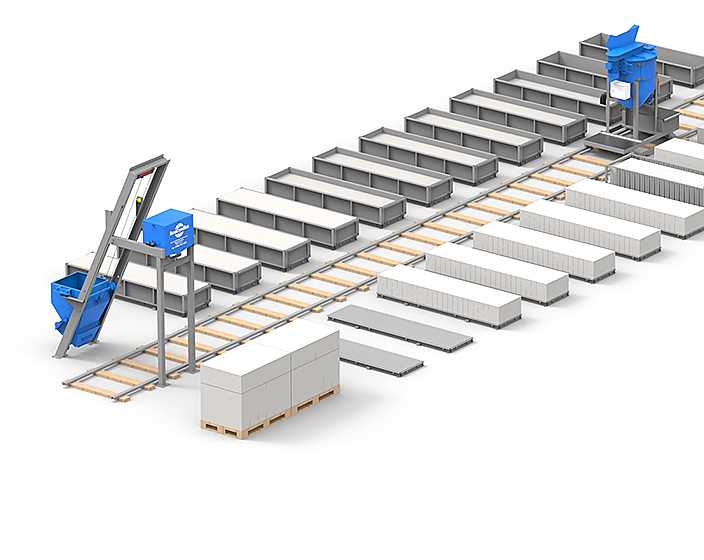

The basic equipment in the conveyor line

|

The mixer-activator |

1 pc. |

|

The suspension mixer |

1 pc. |

|

The cutting pattern and a gang of saws |

1 pc. |

|

Mold pallets with metal bottom |

32 pc. |

|

Mold sides (a set) |

10 pc. |

|

The mechanical pusher |

2 pc. |

|

Frames for the pusher |

2 pc. |

|

The mobility system (rail-tracks, frames, cross-bars), line meter |

36 m. |

|

The transfer cart |

2 pc. |

|

The transfer rail track |

12 m. |

|

The penetrometer |

1 pc. |

|

The scraper to cut the top crust |

1 pc. |

|

The sieve to pour the mix into the mold |

1 pc. |

The calculation of profitability at the example of this line: the costs to produce 1m3of gas-concrete blocks account for 1500 RU on average, the market value – about 2500 RU. Correspondingly, your monthly net profit will account for 1.2 mln RU and above. In the first month of working you will repay expenditures for the equipment.