Aerocrete production lines

Well-chosen equipment for gas-concrete production will provide for a profitable business. “AltaiStroyMash” company is capable of implementing any of your projects on production of gas-concrete blocks. 20 years of our experience in construction engineering and numerous success stories of our customers prove it. You can watch these stories on our website. Now let us present the gas-concrete equipment to you.

Production lines for gas-concrete blocks vary in configuration and productivity, respectively. One should take several parameters into account in order to choose the equipment wisely: the required number of gas-concrete blocks (m3), the room space and the budget.

Our company produces around 200 equipment items and any of them in its configuration means a full-scale plant producing non-autoclave gas-concrete. Unlike producing autoclave gas-concrete where the equipment cost is much higher and the prime cost of the product is 32% higher, our production lines are designed and made so that even a novice can operate them.

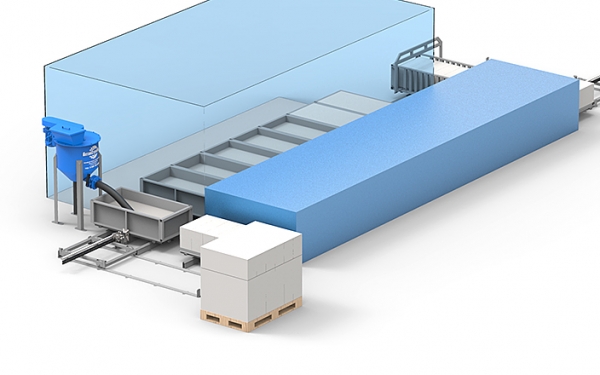

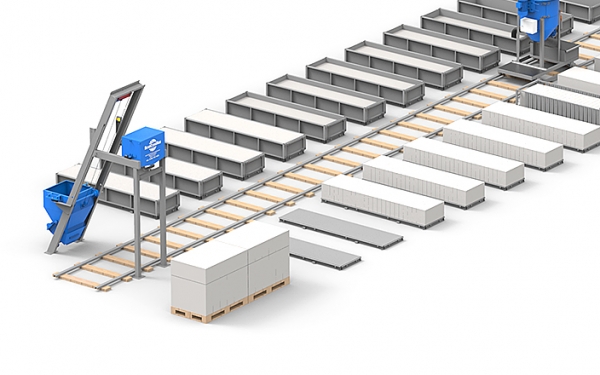

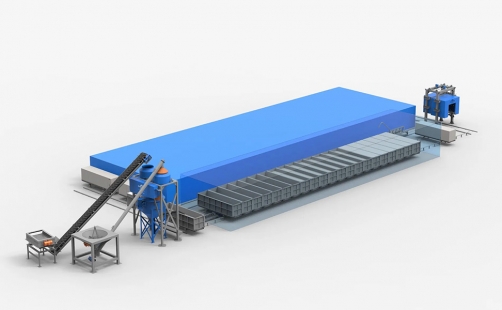

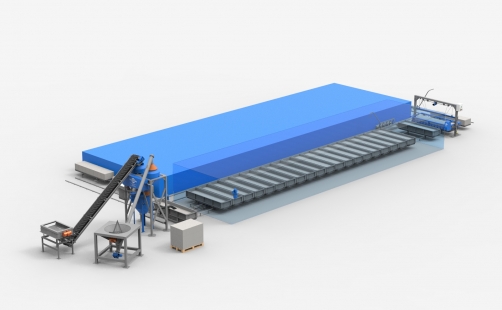

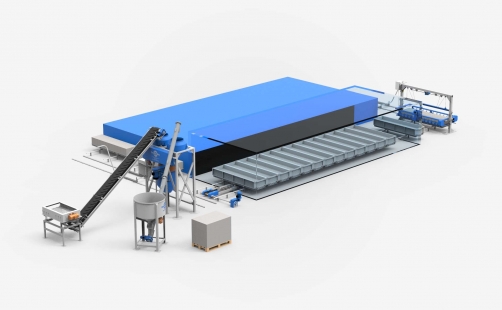

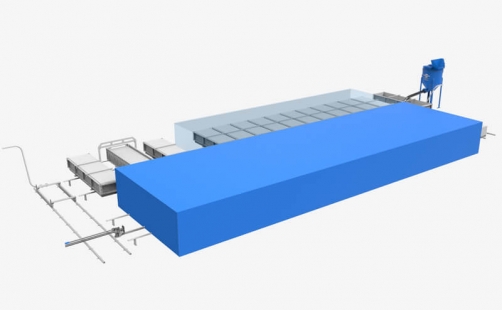

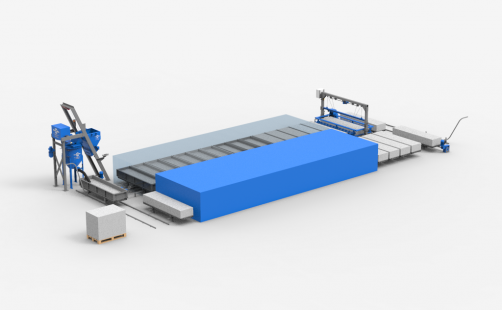

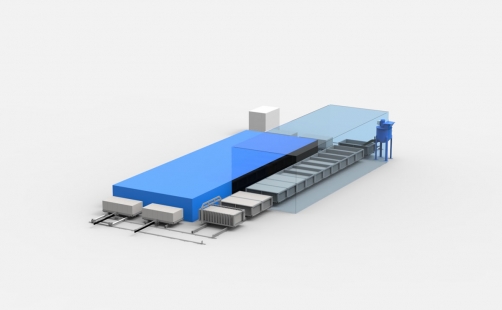

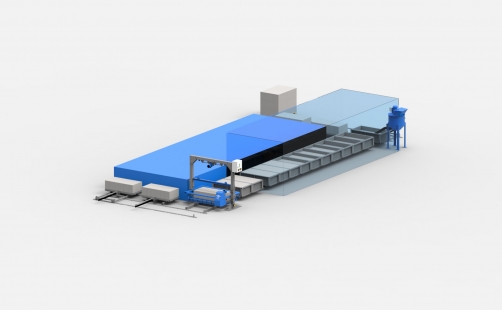

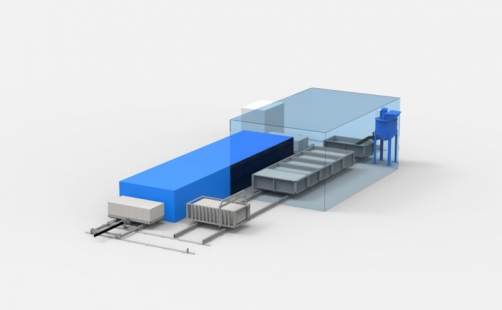

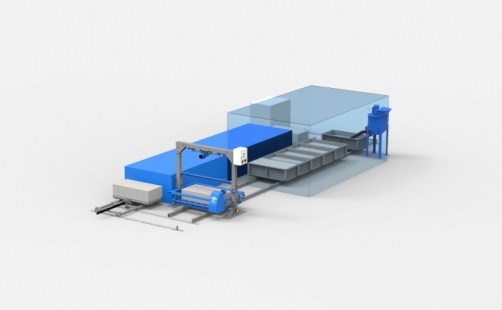

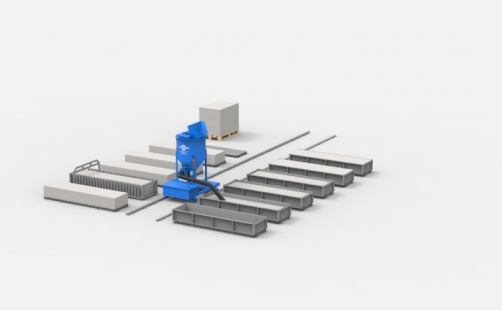

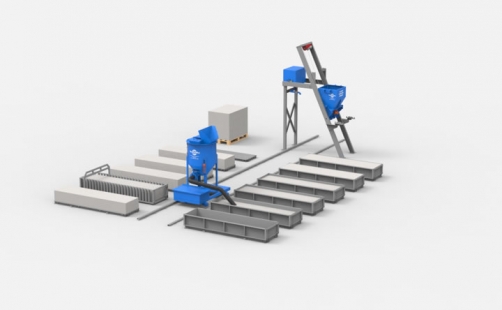

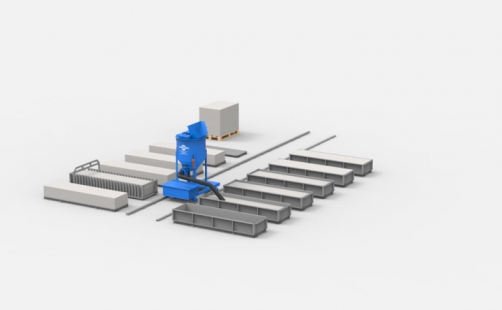

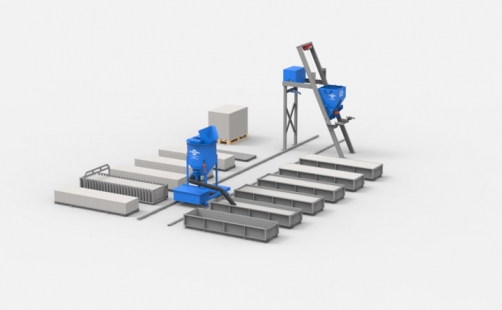

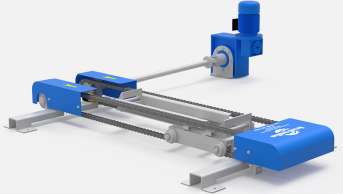

All the lines may be divided into two categories: conveyor-type equipment and stationary equipment. Their major difference is: in the conveyor-type equipment molds are moved via rail tracks and the mixer is stationary whereas in the stationary equipment the mixer is moving via rail tracks along the row of molds.

Conveyor lines are easily automated and save the following:

-

room space, due to the small distance between the molds;

-

labor costs, as the output of products, is located in one place, unlike the stationary-type where the finished gas-concrete blocks have to be collected according to the molds layout.

Stationary lines are easier assembled and any stationary line may be equipped to the conveyor one by installing rail tracks for molds and chambers for major warming and pre-warming and making it completely automated.

Both types contain mini-lines of the conveyor and stationary types. In their turn, they vary in the mixer size and number of molds.

All the equipment is of various productivity ( up to 200 m3/day) and you can choose the best option for yourself — in production capacity and price. The best thing is — any line can be modified:

-

Increasing the number of molds you increase the production capacity of gas-concrete blocks per day;

-

Installing automated slitting you get the block of ideal geometry eliminating the human factor;

-

Adding the automatic feed of sand and cement (weighing dosing unit which measures the feedstock precisely) and you do not depend on the employees' work.

Example: productivity of automated, non-automated conveyor lines and a stationary line in the 200 m2 room.

|

|

Automated conveyor line

|

Non-automated conveyor line

|

Stationary line

|

| Number of workers at production

|

2-4 people

|

2-6 people

|

2-4

|

| Capacity m3/day

|

about 40 m3/day

|

about 40 m3/day

|

20m3/day

|

Whatever your choice is —a mini-line or a large plant producing gas-concrete blocks- our company provides complete professional support at any stage of production: assembling the equipment, testing and commissioning, choosing feedstock, cost calculation, providing a formula of the gas-concrete mixture and marketing the finished product (everything is free of charge). It will help you to produce high-quality gas-concrete blocks.