Polystyrene concrete equipment

The majority of construction objects today are built from construction materials based on advanced technologies. They are more attractive compared to traditional ones due to their affordability and high durability.

Polystyrene concrete has become highly popular as a kind of light concrete (gas-concrete and foam-concrete lie with the same category). It contains polystyrene granules as a filler. According to the European experience, applying polystyrene concrete provides for energy-saving. It is light, conserves heat and provides for great sound-proofing.

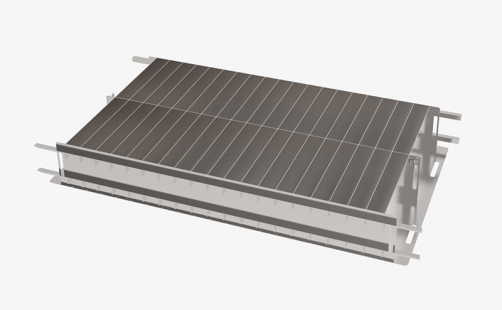

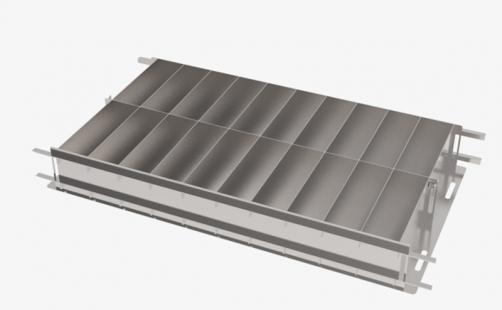

Structure of a polystyrene concrete block

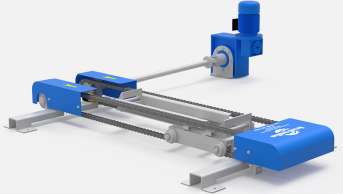

In order to prepare, remove and pour the mixture one needs a mobile unit for polystyrene concrete which provides for producing pieceworks (blocks, boards) as well as solid-cast for heat-insulation and sound-proofing of roofs, floor pouring, solid—cast pouring of self-supporting walls.

Production technology of polystyrene concrete

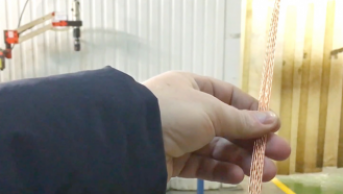

Technological operations for producing polystyrene concrete mixture are quite basic: water is fed into the polystyrene concrete mixer followed by cement and chemical components. The mixture is blended for 1-2 minutes then polystyrene granules are added and the mixture is blended for 1 minute in order to get the homogenous mix. The total time for preparing the mixture including feeding and blending is at least 3-5 minutes. Then the mixture is transported and poured with the gerotor pump through the hose. Its design and mechanism provide for the necessary air volume during the production process.

Transporting, pouring solid-cast polystyrene concrete and shaping blocks.

After the shutters and all necessary connectors are assembled one may start pouring polystyrene concrete into the fixed shutters when constructing exterior walls. The hose goes into the lower part of the shutters and gradually moves along the shutters going higher as the shutters are being filled (similar to molding sectional constructions). Such a pouring technique without vibrocompaction provides for fewer air voids.

When making solid-cast heat insulation of flooring over cold cellars or passages one layer of polystyrene concrete is poured. A leveling board flattens and firms the surface of the pored polystyrene concrete.

When shaping blocks one needs to put the drain hose into the mold and drain the mixture until the cell id filled.

How to purchase the equipment for polystyrene concrete production?

Just contact us in any convenient way: you may call, write an email or fill in an application form at our website. The equipment price is the same for all customers in Russia, Uzbekistan, Kazakhstan, Kyrgyzstan etc. We deliver all over the world and provide a 2-year warranty for all units. Besides, our customers get complete technical guidance of our specialists for the period of operation of the equipment.