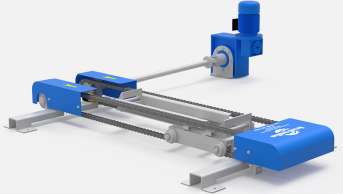

Screw-type conveyors

The working principle of the screw conveyor

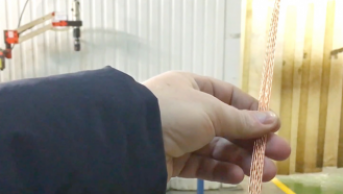

The screw conveyor is applied for leaning or horizontal transporting the bulk materials in various industries. The screw conveyor is applied for transporting fine-fraction, dust-like, powder-like, and bulk materials with coarse fractions up to 10 mm. An important feature of the screw conveyor is its setup at 45ᵒ, which provides for saving the operating area and better access to hubs at various height. Only graded steel is used for producing screws. A metal screw consists of a closed runner and the axis with a spiral inside. Single-start screws are a spiral placed along the closed runner. The screw is working as the spiral is rotating. The feedstock gets into the loading spout and moves in the closed pipe with the help of the rotating screw, its blades transport the material towards the discharge sleeve, so the bulk material is removed to the discharge location.

The screw dimensions (pipe diameter and length) are always special and are specified due to the industry, chosen parameters. It will define the price of the screw. Standard screws are produced in two pipe diameters: 159 mm and 219 mm. the screws have been tested at industries and proved to be highly reliable.

Screw conveyor for bulk materials

Screws are universal equipment applied industrially at both plants and construction sites or warehouses. The screw for bulk materials has proved to be highly reliable. It simplifies transporting, discharging or loading bulk materials.

Benefits of screw conveyors:

-

it is adjustable, easy to maintain, safe and easily installed;

-

the cargo can be transported tilted or horizontally. As it can be installed in a tilted position it saves the operating area, provides for access to hubs at various heights and in hard-to-reach-places. It also can be applied at various industries and sites, (for instance if installed in a tilted position it is used in gas-concrete production, a screw for cement is used for the automation of filling the block of batchers; a screw for corn is used to transport into the tank for storage);

-

the closed screw type provides for working with dust-forming, toxic, fine bulk materials. Since the screw box is air-proof, harmful substances do not penetrate the atmosphere;

-

the screw has a dismountable design, which provides for its easy transportation;

-

the closed runner of the screw conveyor is water-proof, so it may be operated outdoors;

-

the screw is rapidly paid-back since automation increases the productivity and decreases the labor costs;

-

24 months warranty period;

-

we can produce a screw conveyor with the technical features specified by the customer.

The specialists of “AltaiStroyMash” company will assist with choosing the right screw conveyor for your production. We will consider the following parameters: direction, power, distance of transportation, special features of the transported material, loading and discharge peculiarities. Highly-qualified engineers will assist with designing and producing the screw conveyor with complicated and non-standard features. To make and order, just fill in the form at the website or call us at 8 800 100 4454